Research

The AI Foundational Divide: From Ambition to Readiness

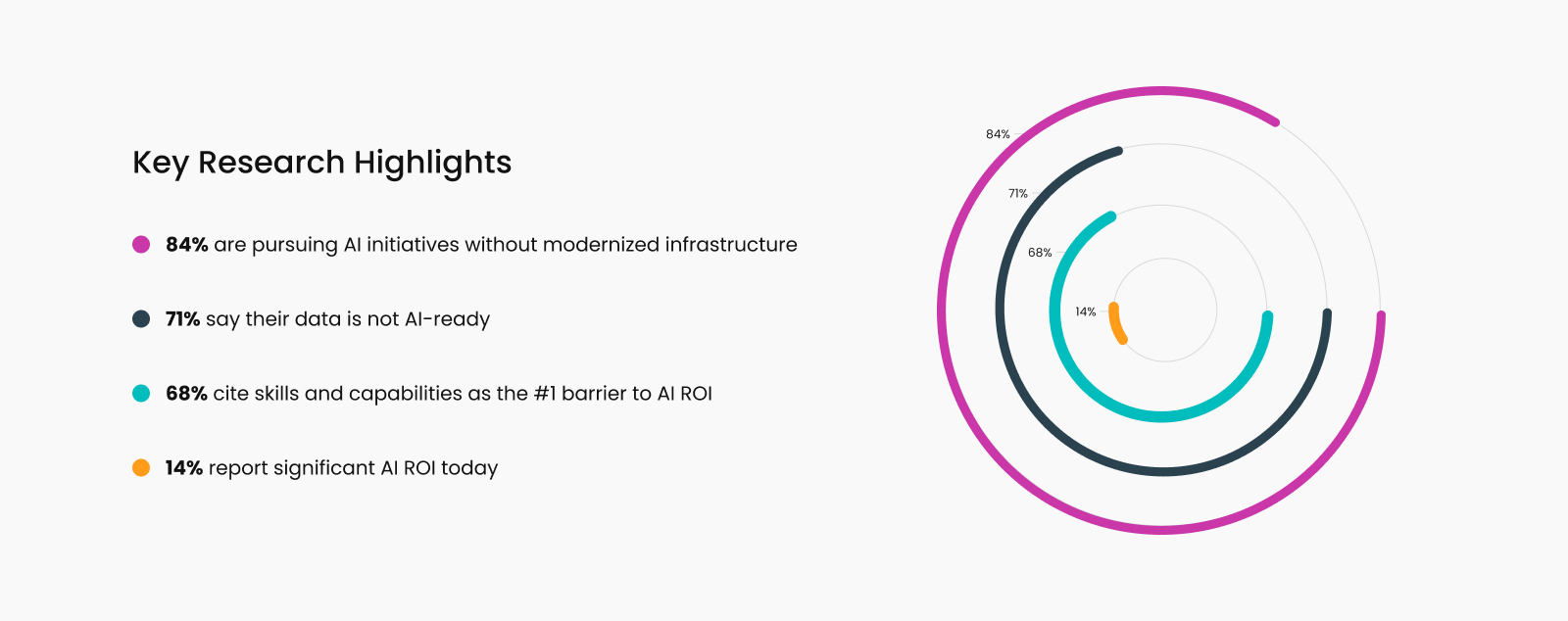

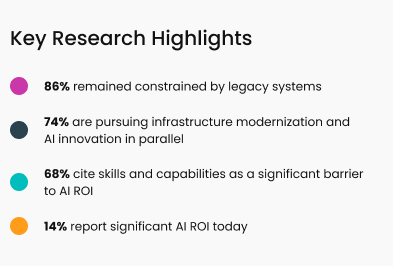

While 66% of CFOs expect measurable AI impact within two years, only 14% are seeing meaningful ROI today. Our latest CFO Research Report reveals what’s really holding organizations back—and what leading enterprises are doing differently.

Subscribe to Mindshift, RGP’s LinkedIn Newsletter

Tap into bold, visionary insights crafted for leaders like you navigating challenges and turning them into opportunities. Each issue delivers fresh ideas, real-world strategies, and expert perspectives to inspire your next move and architect a brilliant future.